Puff Vinyl Temperature And Time: Perfect Press Secrets!

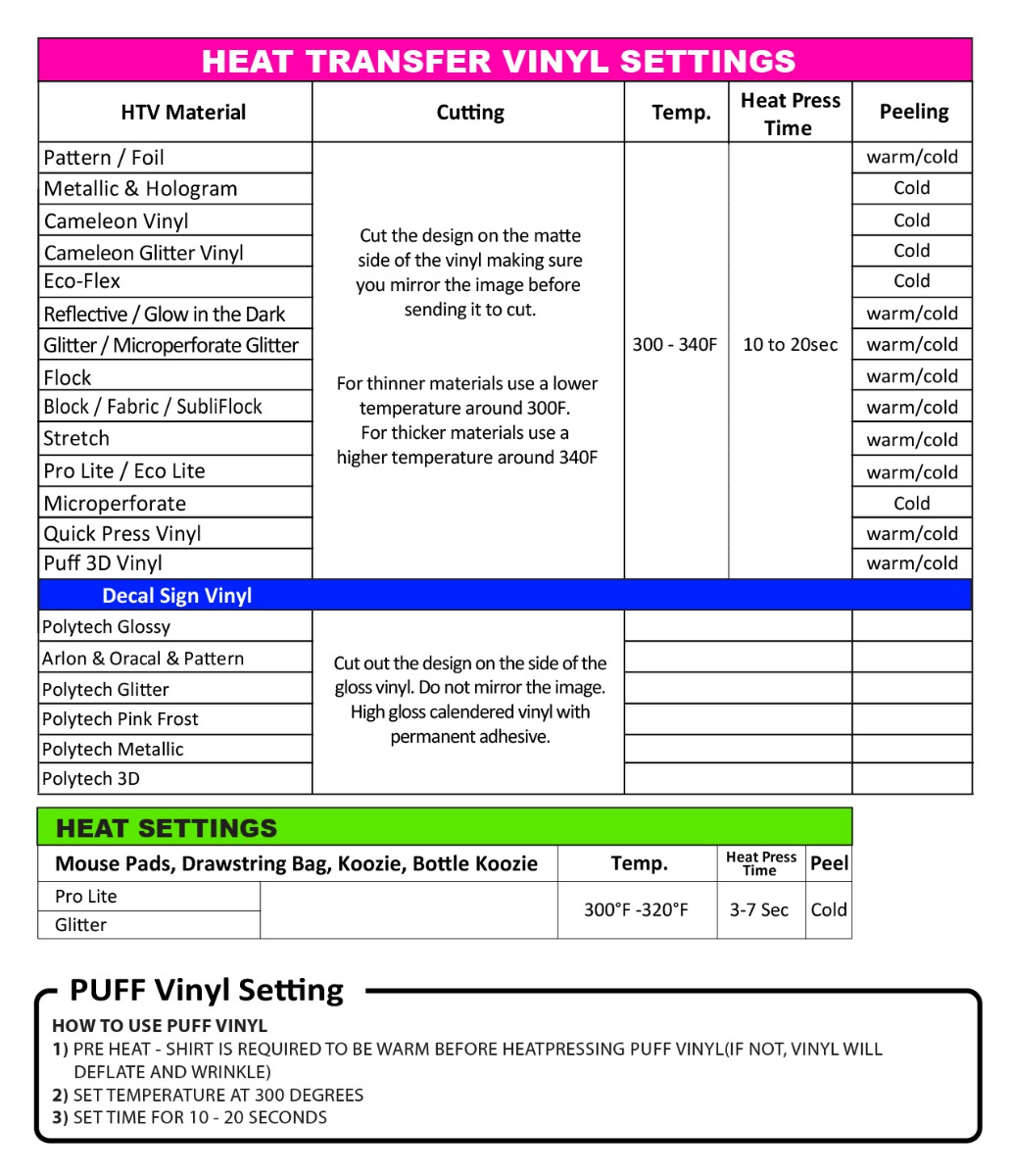

Puff vinyl requires a temperature of 320°F (160°C) and a pressing time of 10-15 seconds. Use these settings to achieve optimal results with puff vinyl transfers.

Puff vinyl, an innovative material in the heat transfer industry, adds a unique dimension to custom apparel and accessories. It’s designed to create a raised, 3D effect on fabrics, making designs pop with an eye-catching appeal. Perfect for both hobbyists and professional printers, puff vinyl is versatile for various projects, from personalized t-shirts to bespoke tote bags.

To ensure a successful application, precise heat and time settings are crucial. The right combination allows the vinyl to expand properly, creating the signature puff effect without damaging the material. Remember to preheat your garment to remove moisture and ensure a clean surface for the best adhesion.

Introduction To Puff Vinyl

Puff vinyl is a specialty material used for creating raised designs on fabric. It’s known for its unique 3D appearance, adding texture and dimension to garments. Designers often choose puff vinyl for its eye-catching effect and versatility.

The use of puff vinyl has grown in fashion and design circles. Its ability to stand out makes it a popular choice for logos, graphics, and custom artwork. This material is especially favored in the production of sports apparel and trendy fashion items, where its bold look can make a statement.

Credit: www.icraftvinyl.com

Essential Equipment For Puff Vinyl Application

To apply puff vinyl successfully, certain equipment is essential. A heat press is crucial for the process, ensuring the vinyl adheres properly. Adjustable temperature control and a timer are key features of a good heat press. Consistent heat distribution across the platen guarantees even application.

For cutting the vinyl, a reliable vinyl cutter is a must-have. It should handle different vinyl types and offer precision in cutting. High-quality blades and adjustable pressure settings contribute to clean cuts, making weeding easier.

Always check the manufacturer’s specifications for the vinyl. This ensures correct temperature and time settings. Using the right tools makes the application process smooth and efficient.

Material Considerations

Fabric types vary in their suitability for puff vinyl applications. It’s essential to match the material with the correct vinyl to ensure optimal adhesion and durability. Cotton, polyester, and cotton-poly blends are often excellent choices for puff vinyl.

Ensuring the puff vinyl’s quality is crucial for long-lasting results. High-grade materials can withstand the necessary heat and pressure during application. This leads to superior finishes and visual appeal.

Temperature Settings Unveiled

The ideal heat range for puff vinyl is crucial for perfect application. It typically lies between 285°F to 320°F (140°C to 160°C). Consistent heat ensures the vinyl expands properly, creating the desired puff effect. A heat press that provides even temperature is essential.

Several factors can influence the optimal temperature settings. Material thickness, color, and brand differences play roles. Pre-testing on scrap material is advised to find the perfect settings. Always follow the vinyl manufacturer’s recommendations for best results.

Timing The Press For Perfection

Finding the right balance for puff vinyl pressing is crucial. Standard press duration often ranges from 10 to 15 seconds. This time ensures optimal adhesion and a smooth finish.

Different materials may require time adjustments. For instance, thicker fabrics might need a longer press time, while delicate fabrics benefit from shorter durations. Testing is key to determine the perfect balance.

| Material | Press Time (Seconds) |

|---|---|

| Cotton | 12-15 |

| Polyester | 10-12 |

| Stretchable Fabrics | 8-10 |

Pressure Matters

Determining optimal pressure for puff vinyl application is essential. The right amount of pressure ensures adhesion and durability. Heat presses vary, so testing is crucial. A good starting point is medium pressure. Look for a press with adjustable settings.

For common pressure issues, start with a check on the press. Ensure it provides even pressure. A pressure gauge helps with accuracy. Uneven pressure leads to poor application. Make sure the press is locked down properly. Use a foam pad for thick garments.

Post-pressing Practices

After pressing puff vinyl, proper cooling is crucial. Ensure the vinyl cools completely before peeling. This prevents distortion and ensures the design’s longevity. Using a cooling block can accelerate the process. It’s essential to avoid rushing this step.

For peeling, specific protocols ensure quality. Cold peel technique is recommended for puff vinyl. Wait until the material is no longer warm to the touch. Then, gently peel the carrier off at a 45-degree angle. This ensures the vinyl’s edges remain intact and prevent lifting. It’s important to peel smoothly and consistently for the best results.

Credit: www.skhouston.com

Advanced Tips And Tricks

Layering puff vinyl can elevate your designs, giving them a unique, tactile dimension. To achieve the desired 3D effects, follow these steps:

- Begin with a preheated base layer applied for just 2-3 seconds.

- Press additional layers individually, using the same short time.

- Ensure the final layer’s temperature and time align with the material’s specifications.

- Cool down between layers to prevent shrinkage.

- Peel off the carrier sheets after each layer’s application.

Proper technique results in eye-catching designs that stand out.

Troubleshooting Common Challenges

To avoid burn marks on puff vinyl, a precise approach is necessary. Correct temperature settings and a consistent heat press time are crucial. Remember, high heat can cause unwanted marks.

Resolving incomplete transfers involves checking the pressure and time. Ensure the press applies even pressure and the timer is set accurately. Examine the vinyl to ensure it fully adheres.

Use a protective cover sheet to prevent direct heat contact. This reduces the risk of burn marks. For incomplete transfers, adjusting the pressure may be required. A test press is also beneficial.

Maintaining Your Heat Press

Ensuring the longevity of your heat press requires some essential practices. Regular cleaning is vital to prevent build-up that can transfer to materials or affect transfer quality. Make it a habit to wipe down surfaces after each use. Use a soft, damp cloth to clean the platen and avoid abrasive materials that could cause damage.

Performing calibration checks is equally important for consistent results. Always verify that the temperature displayed matches the actual platen temperature. An infrared thermometer can provide accurate readings. Regularly test the pressure to confirm it remains even across the platen. This step ensures your puff vinyl adheres properly and durably.

Creative Applications

Creative crafting reaches new heights with puff vinyl. Unique textures elevate simple designs. Custom apparel shines with a three-dimensional twist. Crafting enthusiasts embrace this medium for eye-catching fashion and home decor.

DIY lovers use puff vinyl for personalized gifts. They create stand-out accessories and statement pieces. Puff vinyl’s versatility allows for endless possibilities. It’s perfect for special occasions and branded merchandise.

| Innovative Design Ideas | Inspirational Projects |

|---|---|

| 3D effect on tote bags | Custom pillows with raised patterns |

| Bold typography on shirts | Puff vinyl art canvases |

| Layered stickers for scrapbooking | Decorative kitchenware accents |

Safety Precautions

Handling high temperatures requires careful attention. Use heat-resistant gloves to prevent burns. Always monitor the temperature settings on your equipment. Maintain a safe distance from the heat source while operating.

Ensure workspace ventilation is adequate to dissipate heat. Open windows or use exhaust fans to maintain airflow. This reduces the risk of overheating and maintains a comfortable working environment.

Conclusion: Mastering The Art Of Puff Vinyl

Mastering puff vinyl application takes practice and patience. Perfecting the right temperature and time is crucial. Consistency in these variables ensures high-quality results. Remember, ideal conditions vary based on material and equipment. Practice leads to predictable outcomes and refined techniques.

Stay dedicated to trial and error. It sharpens skills and builds confidence. Document each attempt to track progress. Embrace challenges as learning opportunities. With time, you’ll achieve professional-level craftsmanship. Keep experimenting and never stop learning.

Credit: threelittleferns.com

Frequently Asked Questions

What Temperature Should You Press Puff Vinyl At?

Press puff vinyl at a temperature range of 285-300°F (140-149°C) for optimal results. Always follow specific manufacturer instructions.

What Are The Cut Settings For Puff Vinyl?

For puff vinyl, set your cutter to a medium pressure with a sharp blade. Test cut first, then adjust for a clean, easy weed. Use a heat press at 300°F (149°C) for 10-15 seconds.

What Iron Setting For Puff Vinyl?

Set your iron to a medium to high heat setting, typically between 285°F to 320°F, for puff vinyl application. Always follow the specific vinyl manufacturer’s instructions for best results.

Do You Press Puff Vinyl Twice?

Yes, press puff vinyl twice. The first press adheres the vinyl, and the second press ensures durability and puff effect. Follow the manufacturer’s instructions for best results.

Conclusion

Mastering the art of puff vinyl application transforms your projects into tactile wonders. Remember, the key lies in the precise balance of temperature and time. Perfecting this duo ensures your designs rise to the occasion, both literally and figuratively. Embrace the process, and watch your creations come to life with dimension and durability.